Supply Chain

Supply Chain Overview

The Supply Chain Dashboard helps you monitor your inventory position and provides personalized re-order recommendations. With this tool, you can easily assess your inventory health across your entire business or for specific products. The data is updated daily.

The dashboard is organized into three main sections:

Inventory Health Block: Offers an overview of your inventory, highlighting the number of SKUs that are out of stock, in low stock, or in excess stock.

Performance Tracker (Year-over-Year): Compares the units sold this year to those sold in the prior year, allowing you to quickly identify shifts in product demand and seasonal trends.

KPIs by Product Table: Provides a comprehensive list of inventory KPIs per SKU, helping you understand your precise inventory position and determine when and how much to re-order.

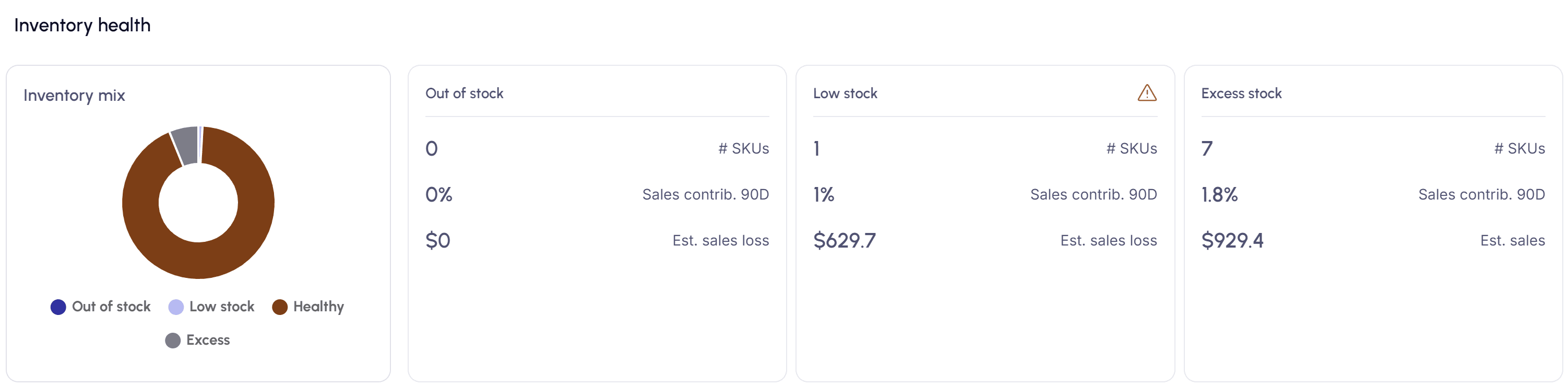

Inventory Health

The Inventory Health block consists of four key tiles that provide a detailed snapshot of your inventory status:

Inventory Mix: A pie chart displaying the distribution of SKUs that are currently out of stock, in low stock, in healthy stock, or in excess stock.

Out of Stock:

Shows the number of SKUs that are out of stock. By default, a SKU is considered out of stock if there are fewer than 7 days of inventory remaining.

Displays the sales contribution (in %) of these SKUs over the last 90 days.

3fin provides an estimate of potential sales loss based on historical demand.

Low Stock:

Indicates the number of SKUs currently low on stock. By default, a SKU is considered low on stock if there are between 8 and 30 days of inventory remaining.

Displays the sales contribution (in %) of these SKUs over the last 90 days.

3fin estimates potential sales loss based on historical demand.

Excess Stock:

Identifies the number of SKUs currently in excess stock. A SKU is considered in excess if there are more than 180 days of inventory available at Amazon’s fulfillment centers. Be aware that long-term storage fees may apply for excess stock.

Displays the sales contribution (in %) of these SKUs over the last 90 days.

3fin provides an estimate of expected sales for these SKUs over the next 90 days.

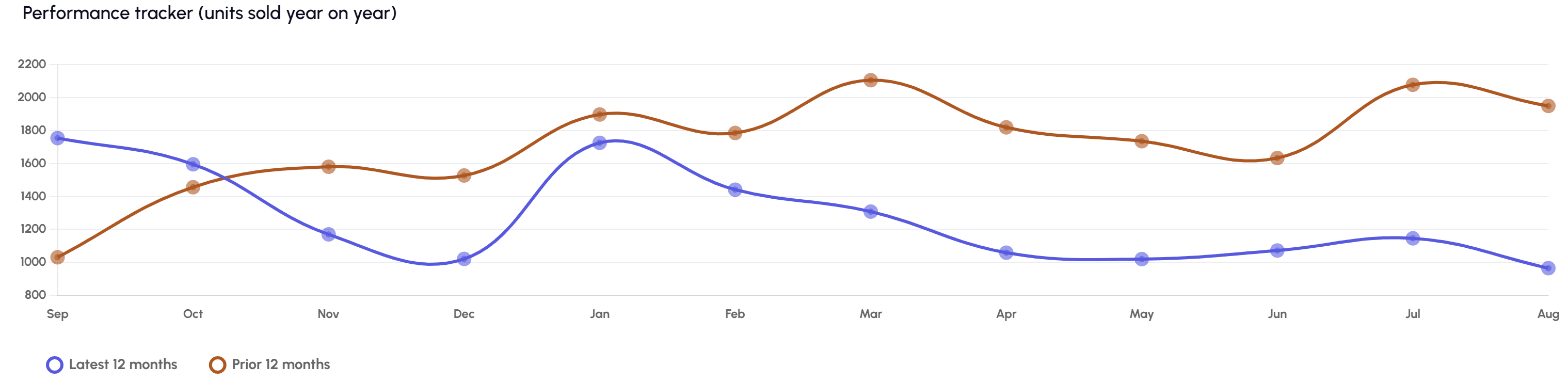

Performance Tracker (units sold year on year)

The Performance Tracker chart enables you to compare the units sold this year against those sold in the prior year, helping you quickly identify shifts in product demand and seasonal trends. The chart reflects the filters selected at the top of the dashboard, including marketplace, brand, and product.

Please note that the chart only accounts for units sold and successfully shipped. Cancelled orders are excluded since they have not been shipped.

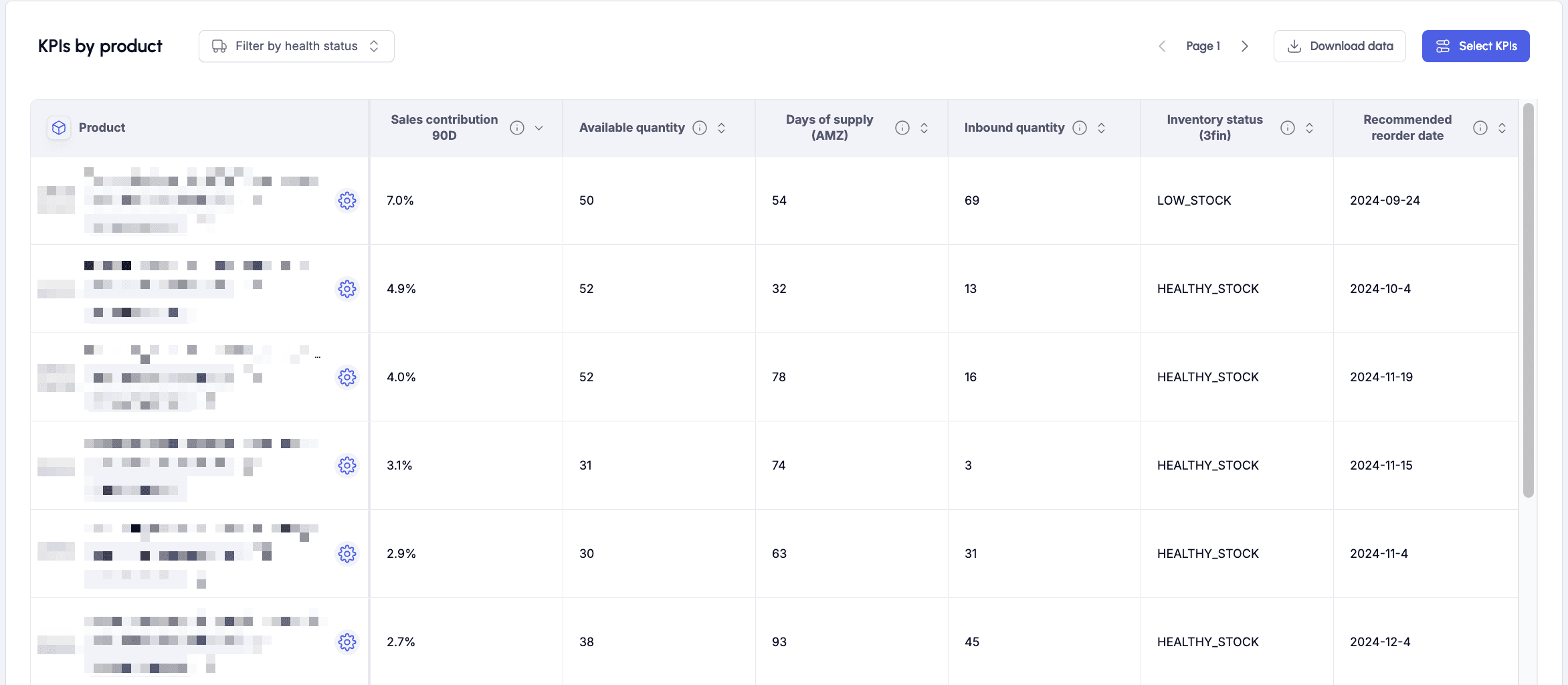

KPIs by Product

Inventory Table Overview

The Inventory Table provides comprehensive information about your inventory for all SKUs in your portfolio. It details the inventory status of each SKU (health, excess, out-of-stock, low stock) and offers personalized reorder dates and quantities based on your preferred minimum inventory levels.

By default, the Inventory Table displays the following key metrics to help you understand your inventory position and take appropriate actions:

Sales Contribution 90D: The percentage of total sales from the last 90 days that each product contributes, calculated as the product's sales over the last 90 days divided by the total sales of your entire portfolio over the same period.

Available Quantity: The number of sellable units in stock, ready to fulfill orders. This metric excludes units pending removal and is calculated in real-time.

Days of Supply (AMZ): The estimated number of days your current inventory will last based on projected demand, as calculated by Amazon.

Inbound Quantity: The total number of units that are inbound, including working, shipped, and receiving units. Note that this may differ from the quantity shown in "Manage Inventory Inbound," which only includes shipped units.

Inventory Status (3fin): The health status of each SKU’s inventory, categorized as Out of Stock, Low Stock, Healthy, or Excess. This status is determined based on your preferences (see the “Setting up Inventory Preferences” section below). By default, 3fin uses Amazon's Days of Supply metric and applies the following thresholds:

Out of Stock: 7 or fewer days of supply remaining.

Low Stock: 8 to 30 days of supply remaining.

Healthy: 31 to 180 days of supply remaining.

Excess: More than 180 days of supply remaining.

Recommended Reorder Date: Based on the ideal days on hand you have defined in the inventory preferences for the SKU.

Recommended Reorder Quantity: Calculated based on your inputs, such as safety stock and target stock range after reordering, as defined in the inventory preferences for the SKU.

Total Quantity: The sum of Available Inventory and Incoming Inventory.

Sales Velocity 90D: The average number of units shipped per day over the last 90 days, calculated as Units Shipped 90D / 90.

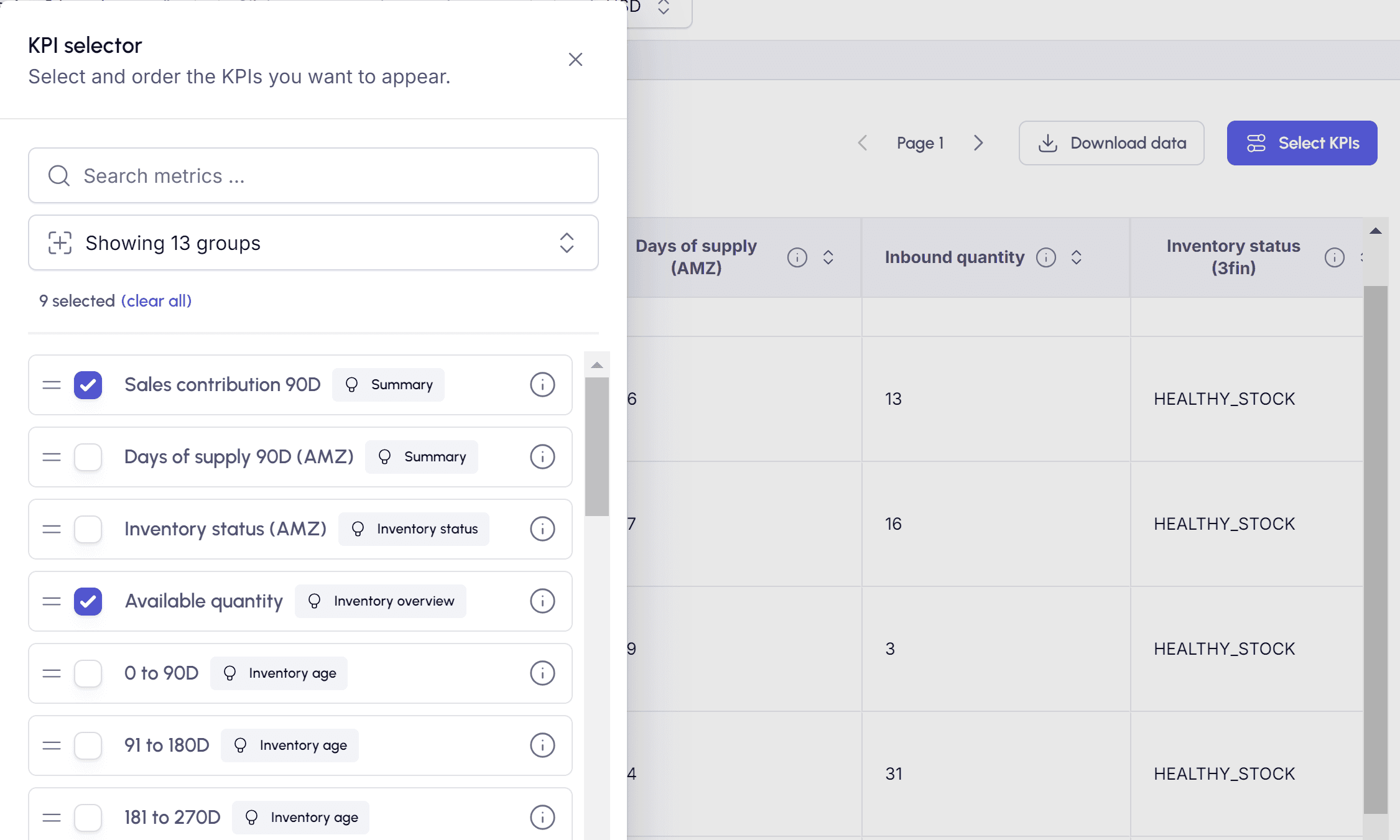

Customizing the Inventory Table

If you wish to customize the Inventory Table with other metrics, simply use the “Select KPIs” button in the top right corner to add or remove metrics (columns) being displayed. The KPI selector allows you to choose metrics from 13 different categories:

Summary: Includes metrics such as days of supply left (based on trailing 90 days demand), inventory status calculated by 3fin, and the SKU’s sales contribution over the past 90 days.

Inventory Status: Reflects the SKU’s inventory health according to Amazon, categorized as Out of Stock, Low Stock, Healthy, or Excess.

Inventory Overview: Contains metrics related to your inventory position across the supply chain, including available quantity, inbound quantity, and more.

Inventory Age: Provides metrics related to the age of your inventory, such as the number of sellable units that have been in Amazon’s fulfillment centers for various time periods (e.g., “0 to 90 days,” “181 to 270 days”).

Units Shipped: Includes metrics related to the number of units shipped over the last 7, 30, 60, and 90 days.

Recommendations: Displays Amazon-provided inventory recommendations.

Sell-Through Rate: Includes Amazon's calculated sell-through rate, defined as Units Sold 90D / Average Inventory Available 90D.

Days of Supply: Shows metrics related to the number of days of supply remaining, based on different sell-through rates.

Weeks of Cover: Displays metrics related to the number of weeks of supply remaining, based on different sell-through rates.

Sales Shipped: Provides metrics for sales shipped over the last 7, 30, 60, and 90 days.

Storage Cost: Estimates the storage cost for the upcoming month, as provided by Amazon.

Sales Velocity: Shows sales velocity metrics for various date ranges: last 7, 30, 60, and 90 days.

3fin Recommendation: Includes the recommended reorder quantity and date, based on your inputs.

Setting Up Customized Inventory Preferences

You can set up custom inventory preferences for each SKU by clicking the blue settings icon located next to each product in the first column (“Product”) of the Inventory Table.

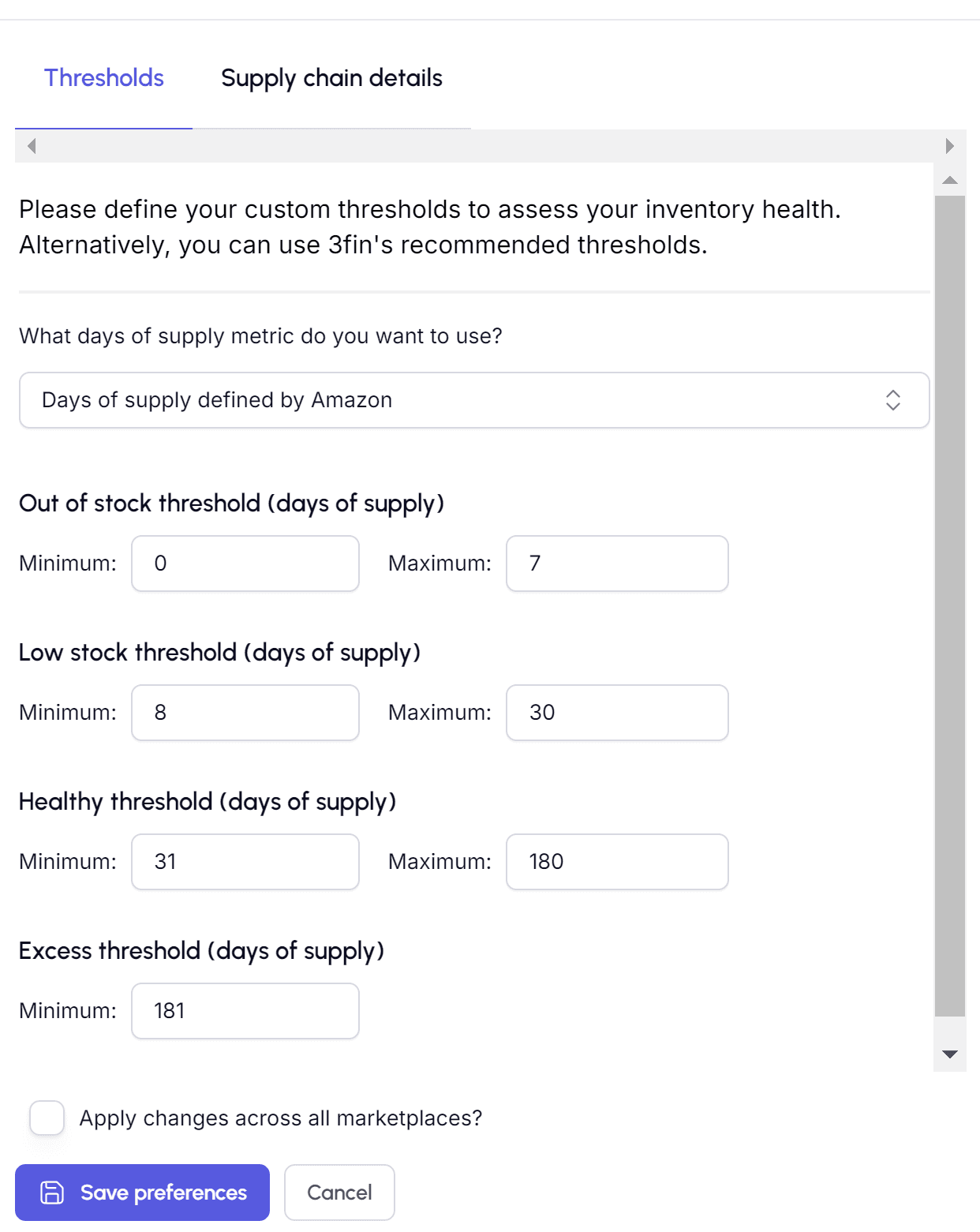

Defining Thresholds

You have the option to define custom thresholds for assessing your inventory health or use 3fin's recommended thresholds. To set your own thresholds, follow these steps:

Step 1: Use the dropdown menu to select which days of supply metric you want to use. You can choose from the following options:

Days of supply defined by Amazon (default)

Days of supply 30 days, based on your last 30 days of sales performance

Days of supply 60 days, based on your last 60 days of sales performance

Days of supply 90 days, based on your last 90 days of sales performance

Step 2: Set the minimum and maximum days of supply thresholds for each inventory status.

Step 3: Decide if you want to apply these changes across all marketplaces.

Step 4: Click the “Save Preferences” button to confirm your settings.

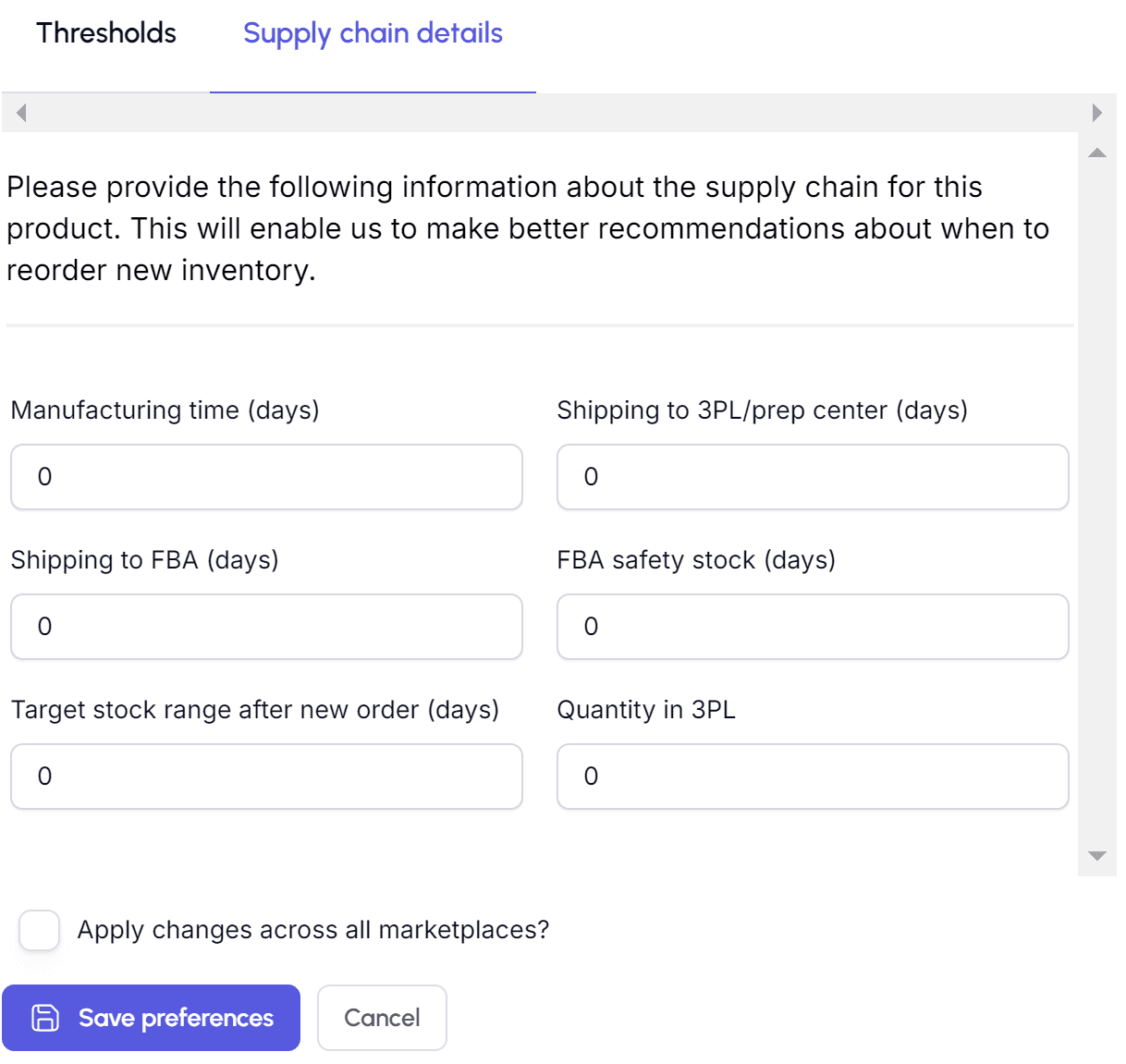

Supply Chain Details for Reorder Recommendations

To receive personalized reorder dates and quantities from 3fin, you must provide specific supply chain details for the selected SKU. To do this, click the blue settings icon next to each product in the first column (“Product”) of the Inventory Table, then select “Supply Chain Details.”

Provide the following information to help 3fin generate accurate recommendations for when to reorder new inventory:

Manufacturing Time (days): The time it takes your supplier to manufacture the products.

Shipping to FBA (days): The time required to ship the products:

If you do not use a 3PL/prep center: The time from your supplier to Amazon’s fulfillment centers, including Amazon's processing time.

If you do use a 3PL/prep center: The time from your 3PL/prep center to Amazon’s fulfillment centers, including Amazon's processing time.

Target Stock Range After New Order (days): The desired number of days of supply you want available after placing a purchase order.

Shipping to 3PL/Prep Center (days): The time it takes to ship the products from your supplier to your 3PL or prep center.

FBA Safety Stock (days): The minimum inventory (safety stock) you wish to maintain at Amazon’s fulfillment centers at all times.

Quantity in 3PL: The current quantity of stock available at your 3PL.

Once you’ve entered all the required information, do not forget to save your preferences. 3fin will then automatically calculate optimal reorder quantities and date.

How does 3fin calculate the optimal reorder date and quantity?

Recommended Reorder Date: Today’s Date + Days of Supply Left - Safety Stock - Total Lead Time

Recommended Reorder Quantity: (Total Lead Time * Days of Stock) + Safety Stock

If none of the “Supply Chain Details” are filled out, the re-order date and quantities will remain blank.